A man who barely knows of my existence but who was a tremendous influence on me as a repairman and a musician is Eric Swanson (who is the bass trombonist with the wonderful Dallas Opera Orchestra and who runs a great shop out of his garage in Fort Worth).

I once brought him a Yamaha euph with a jammed piston. It was the one with the bottom of the case that was blocked by some valve tubing. He looked it over and determined that it was likely jammed up due to being dirty. (This ended up being correct. The friend who loaned it to me had purchased it used and had never had it chem-cleaned.) The issue was that there was no way to gently tap the piston out of the casing from below, and pulling it out could cause more damage if something else was causing it to stick. He said to me, "I am sick of this problem coming across my bench and each time having to reinvent the wheel to solve it. Let me make a tool to do this." I agreed, but my destitute student self was worrying about dollar signs clicking past while Eric worked on the horn.

He chatted with me as he cut off a short length of broom handle (his wife caught him doing this and expressed her displeasure heh, heh…) and he drilled a 45º hole, cut a dowel, and glued it into the hole. This went on for a little while. Finally, he sat at his bench with the tool and the euph, and said, "Just a reminder: I charge by the hour." Then he slapped a timer, put the tool in place, tapped it once, caught the piston as it fell free, slapped the timer again, and stated "TEN BUCKS!" with a big smile on his face.

HAHAHA!!!

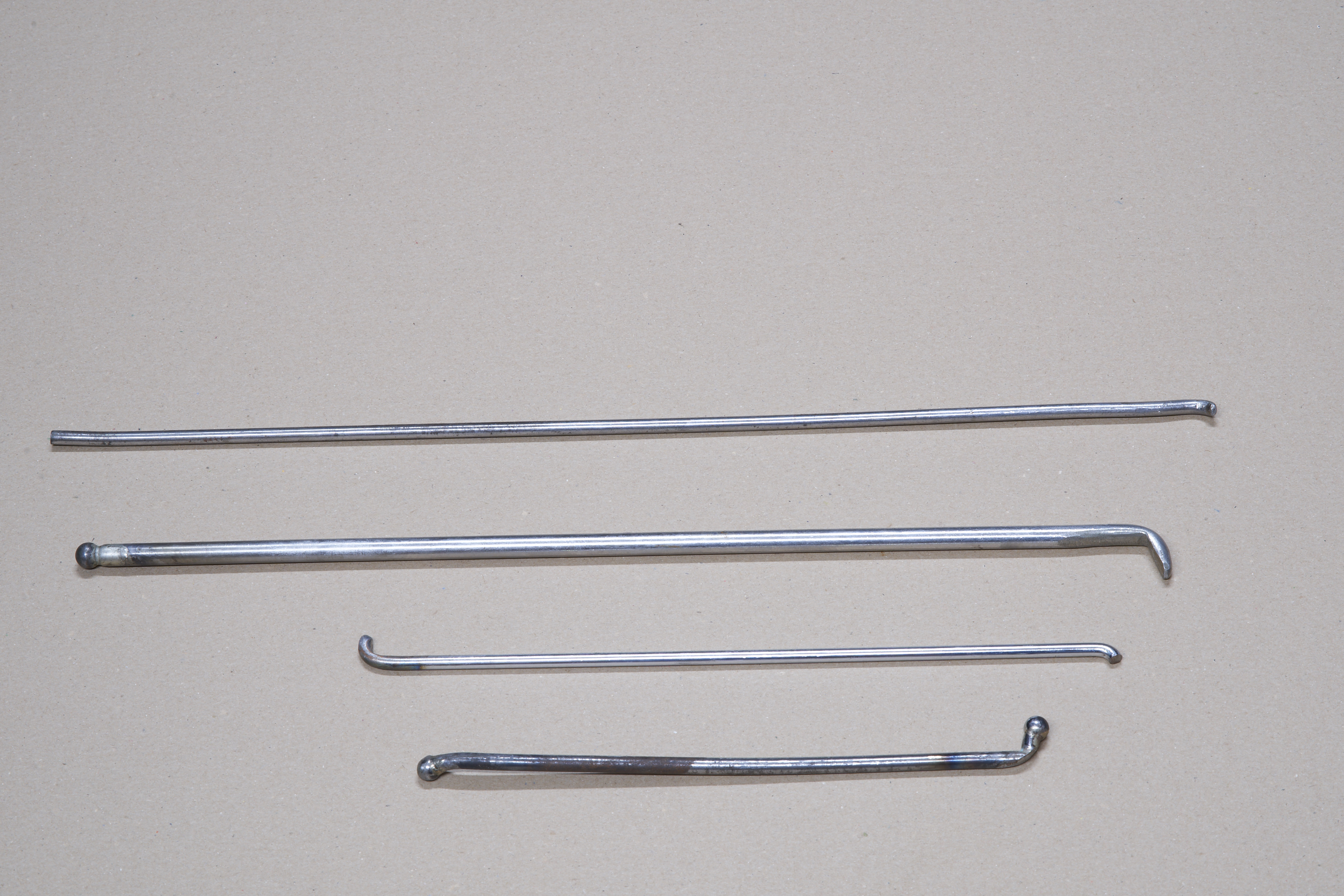

Anyway, one of the first sets of tools that I made that were good enough to keep and use for many years was my set of violin soundpost setters. I had only ever seen someone use them, but not had a chance to look at the tools themselves. Once I knew what I had to do, making a set from an old coat hanger was pretty simple, and what I ended up with is remarkably close to the actual tools. (Necessity can be a real mother, to paraphrase…)

These two bits of coat hanger wire have made me thousands of dollars over the last 25 years…

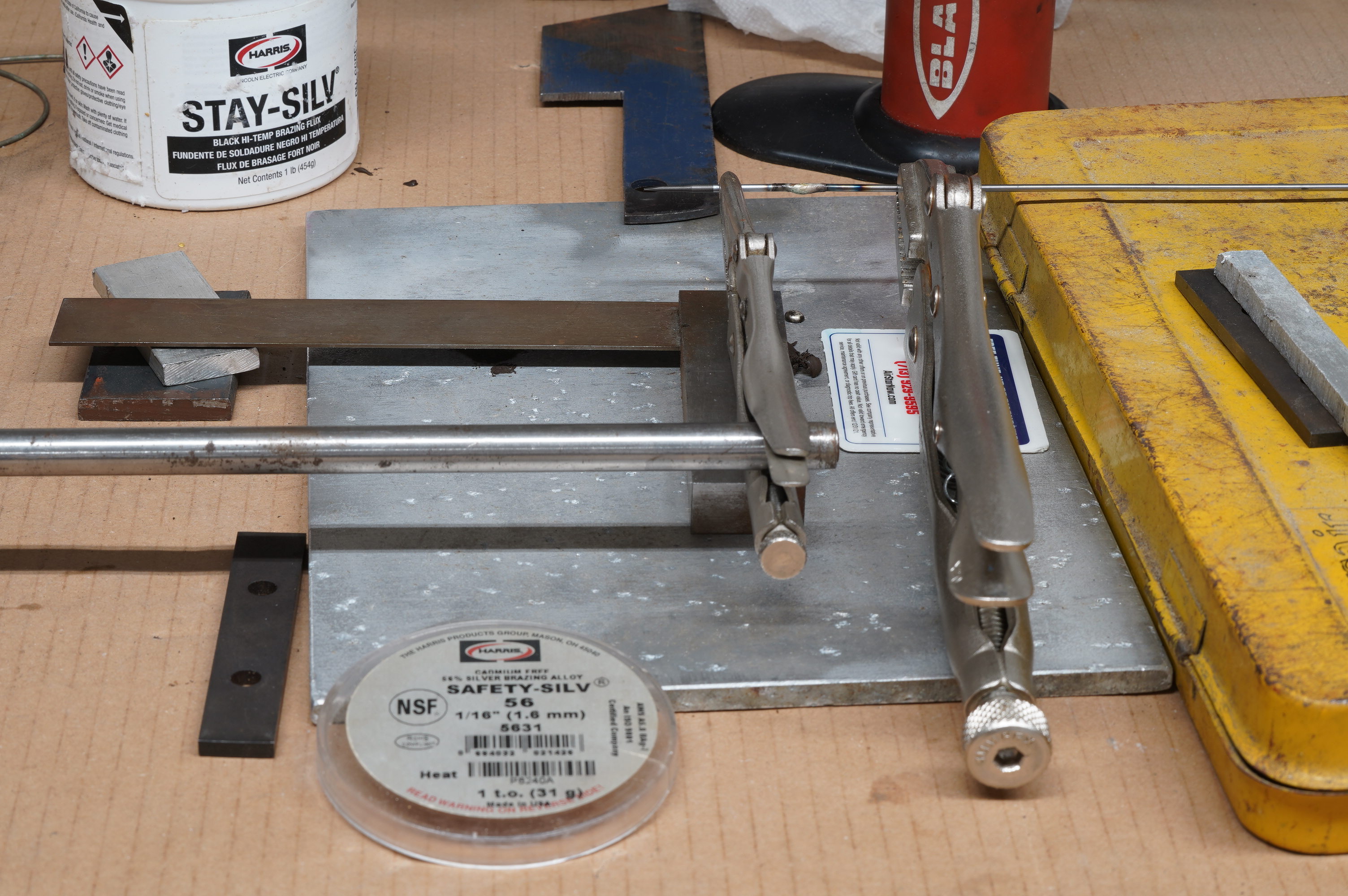

Right now I am building a jig to center drill long, thin rods to tap and then install threaded couplers.

I am sick of my wobbly drill press. I am currently hunting down the specific one I want (which is, of course: old, no longer made, bombproof, with bearings and such that are still available, fully rebuildable, "American Iron" to replace an inaccurately made, uncorrectable pile of off-shore junk). I have been doing my research and my due diligence on the phone and may have located one that ticks two of the three boxes of searching for vintage tools:

• good quality

• good price

• good location

In this case, the price and condition balance each other out and are very good, but the location is about a six-hour drive from my location, and that sucks. However, the quality and condition of what I am picking up make up for the combined cost of the item and the cost of the trip, so all I really am out is a lot of time. Whatever. It may already have been sold. I am awaiting a response from the seller, and it is the holidays, so he may not even be in the US right now. We shall see. My fingers are crossed.

So, back to my idea of a dedicated end-drilling jig…

I have been farting around with old US-made Jacobs drill chucks, as they are about as accurate as you can get in my price range. I own five of them. My Delta bench motor came with one on it. I replaced the horrid abortion of a chuck on my Ryobi drill press with another that I got from eBay and cleaned up. I have a few more of various sizes and tapers.

One of these is a really nice Jacobs #7B. I am hoping to make a sort of upright lathe tailstock for the drill press I hope to soon own. I know a lot of "old man" tricks to use an accurate drill press as a sort of lathe, and I plan to make a tool specific to my needs to use these tricks. (Yeah, I am getting a lathe, but I first have to find a place to set it up that is cat-safe. That is a "must" item.) This upright tailstock would hold the cutting bits, and the drill press would spin the rod to be drilled out.

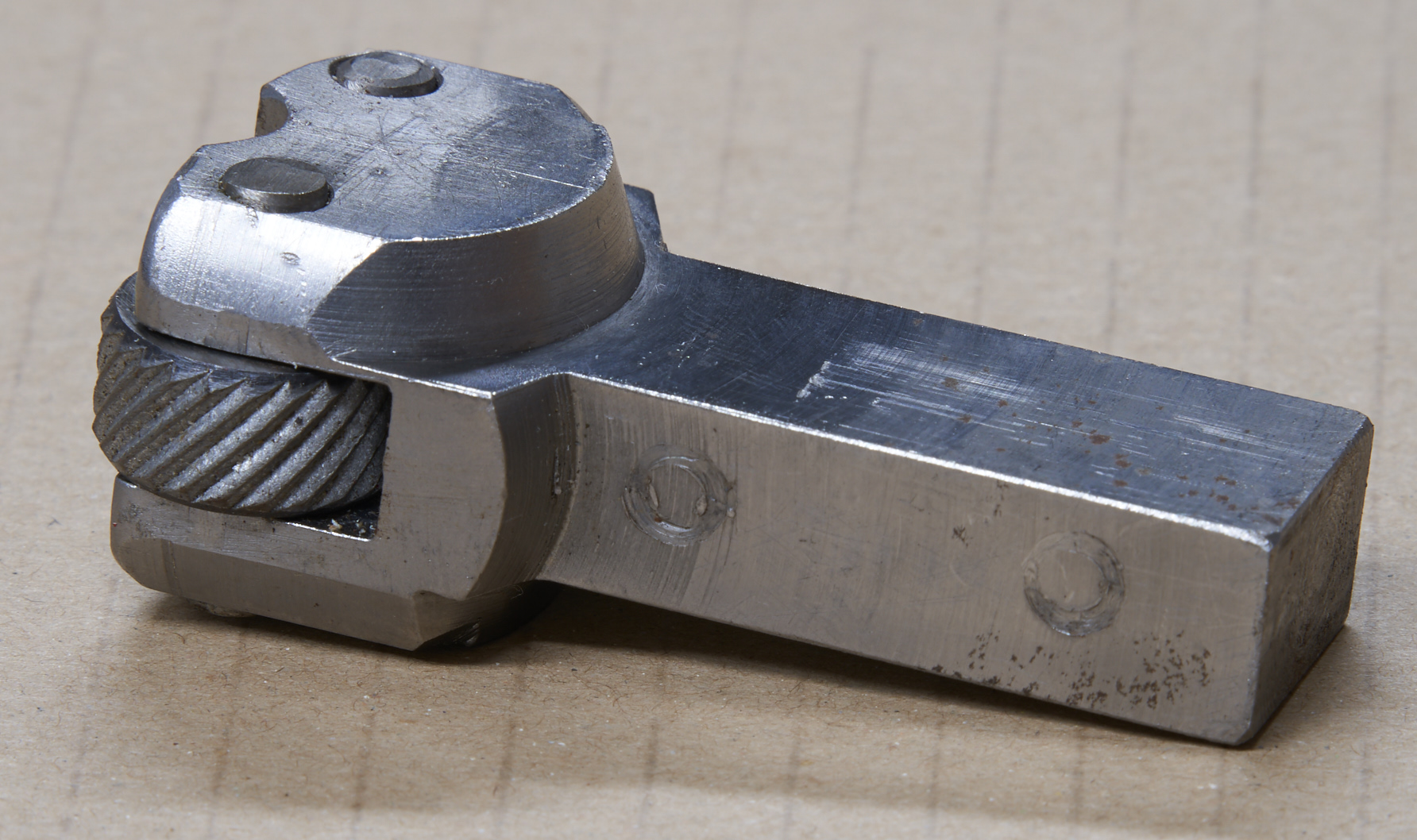

In my search for parts for this upright tailstock, I have been buying up small Jacobs Chucks, which are usually very inexpensive. I just picked up a #0, which is tiny. The barrel is not much bigger around than my thumb. It is listed in old catalogs as being for a hand drill, but I have never seen this small of a chuck on anything. It is very cool and it works pretty well. I have to punch it apart so I can clean and service it. I see no indications of it being damaged, and it was made at the Hartford, Connecticut factory (probably in the 1960s), so it is just about bombproof.

SIDEBAR RANT: The current China-made Jacobs Chucks (available at Harbor Freight) are made from very soft steel and can no longer tolerate being disassembled according to the company's instructions — they quickly become malformed, so to service one is to ruin it. They are pretty much expensive, disposable chucks. Normal use wears them out, and they can't be repaired.

Here is the little #0 chuck. As far as drill chucks go, it's a pretty cute, little fellow. I hope to use it in another project like the upright tailstock. What do you think I should use it for? (Keep it clean, you weirdos…)

JACOBS CHUCK

That is my pinky at the bottom…

I was pleased that, as old as this is, the jaws do not need to be replaced.

HARTFORD, CONN.

U.S. OF AMERICA

AirPods for size reference…